Bookkeeping

15 5: Actual Vs. Applied Factory Overhead Business LibreTexts

Knowing the total and component costs of the product is necessary for price setting and for measuring the efficiency and effectiveness of the organization. Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs. Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing..

Calculate Material Costs

This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit. Hence, one of the major advantages of predetermined overhead rate formula is that it is useful in price setting. For example, assume a company expects its total manufacturing costs to amount to $400,000 in the coming period and the company expects the staff to work a total of 20,000 direct labor hours. In order to calculate the predetermined overhead rate for the coming period, the total manufacturing costs of $400,000 is divided by the estimated 20,000 direct labor hours.

Resources for Your Growing Business

By using the predetermined rate product costs and therefore selling prices can be calculated quickly throughout the year without the need to wait for actual overheads to be determined and allocated. In addition while manufacturing overheads might vary seasonally throughout the year, the use of a constant predetermined rate avoids a similar variation in unit product cost. If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows. Using the predetermined overhead rate formula and calculation provides businesses with a percentage they can monitor on a quarterly, monthly, or even weekly basis.

Determining Estimated Overhead Cost

Once you have identified your manufacturing expenses, add them up, or multiply the overhead cost per unit by the number of units you manufacture. So if you produce 500 units a month and spend $50 on each unit in terms of overhead costs, your manufacturing overhead would be around $25,000. Job costing, also called project-based accounting, is the process of tracking pohr formula costs and revenue for each individual project. Job costing looks at each project in detail, breaking down the costs of labor hours, materials, and overhead. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,450. The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,600.

Create a Free Account and Ask Any Financial Question

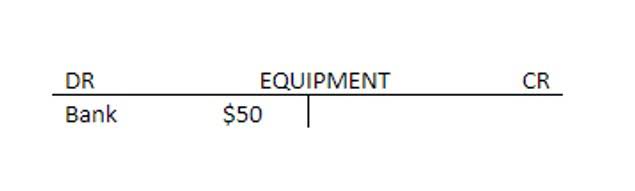

In contrast, the traditional allocation method commonly uses cost drivers, such as direct labor or machine hours, as the single activity. Now that you’ve calculated your predetermined overhead rate, you can apply it to jobs for the purpose of job costing as the applied overhead cost. As you have learned, the overhead needs to be allocated to the manufactured product in a systematic and rational manner.

- The rate is determined by dividing the fixed overhead cost by the estimated number of direct labor hours.

- If a job in work in process has recorded actual labor costs of 6,000 for the accounting period then the predetermined overhead applied to the job is calculated as follows.

- Unexpected expenses can be a result of a big difference between actual and estimated overheads.

- This means that once a business understands the overhead costs per labor hour or product, it can then set accurate pricing that allows it to make a profit.

- Hence, the overhead incurred in the actual production process will differ from this estimate.

Profit Maximization

With semi-variable overhead costs, there will always be a bill (a fixed expense), but the amount will vary (a variable expense). There are a few business expenses that remain consistent over time, but the exact amount varies, based on production. For example, companies have to pay the electricity bill every month, but how much they have to pay depends on the scale of production. For instance, during months of heavy production, the bill goes up; during the off season, it goes down. Any type of business can benefit from job costing, from construction companies to accounting firms.

- To allocate overhead costs, an overhead rate is applied to the direct costs tied to production by spreading or allocating the overhead costs based on specific measures.

- Also, if the rates determined are nowhere close to being accurate, the decisions based on those rates will be inaccurate, too.

- Again the actual overhead at the end of the accounting period is 1,575 and the overhead is said to be under applied by 81 (1,494 – 1,575) as shown below.

- The controller of the Gertrude Radio Company wants to develop a predetermined overhead rate, which she can use to apply overhead more quickly in each reporting period, thereby allowing for a faster closing process.

- If the actual overhead at the end of the accounting period is 1,575 the overhead is said to be under applied by 75 (1,500 – 1,575) as shown in the table below.

- In order to find the overhead rate we will use the same basis that we have chosen by multiplying this basis by the calculated rate.

Calculating Manufacturing Overhead Cost for an Individual Job

The overhead will be allocated to the product units at the rate of 10.00 for each machine hour used. Also, if the rates determined are nowhere close to being accurate, the decisions based on those rates will be inaccurate, too. After reviewing the product cost and consulting with the marketing department, the sales prices were set.

- To avoid such fluctuations, actual overhead rates could be computed on an annual or less-frequent basis.

- The common allocation bases are direct labor hours, direct labor cost, machine hours, and direct materials.

- Creating a job cost sheet helps companies stay profitable by taking stock of how much past jobs have cost, allowing business owners to make changes to improve efficiency and reduce costs.

- You would then take the measurement of what goes into production for the same period.

- Overhead is the most difficult cost to calculate because you’ll need to rely on an approximation instead of the actual cost.

- This is a particular concern in highly competitive industries where production rates may vary dramatically, based on the popularity of the latest round of product releases.

- The cost of goods sold consists of direct materials of $3.50 per unit, direct labor of $10 per unit, and manufacturing overhead of $5.00 per unit.

- This chapter will explain the transition to ABC and provide a foundation in its mechanics.

- A company that excels at monitoring and improving its overhead rate can improve its bottom line or profitability.

- For example, Figure 4.18 shows the monthly costs, the annual actual cost, and the estimated overhead for Dinosaur Vinyl for the year.

- In this case, for every product you manufacture, you allocate $25 in manufacturing overhead costs.

- Management analyzes the costs and selects the activity as the estimated activity base because it drives the overhead costs of the unit.